The new SAP S4/HANA technology brings new functionalities and a number of process changes. Production Version management is part of this functional evolution. Optional in the ECC version, they become mandatory in the new S4/HANA version, for all types of production: Discrete Manufacturing, Process Manufacturing and Repetitive Manufacturing.

Let's discover in this article how to manage Production Version from A to Z.

Requirements

To begin, it is important to define the basics and give some definitions.

Routing : A representation of how you handle work at your level. Typically, a routing consists of a series of operations, also called routing steps. However, a routing may include other steps, such as holding or scrapping, or other routings.

BOM (Bill of Material) : A bill of materials (BOM) is a list of materials, assemblies, components and parts needed to make a product. They can be used to define simple relationships where one component has multiple subcomponents. If necessary, you can define a maximum and minimum quantity for each material and each class in the BOM.

Production Version : A production version determines which alternative BOM is used with which routing or master recipe to produce a material or create a master production schedule. For a material, you can have several production versions, for various validity periods and lot size ranges.

Source : https://help.sap.com/

Now that the foundations have been laid, we can present the principle of operation of Production Versions.

Production Version :

What's the objective?

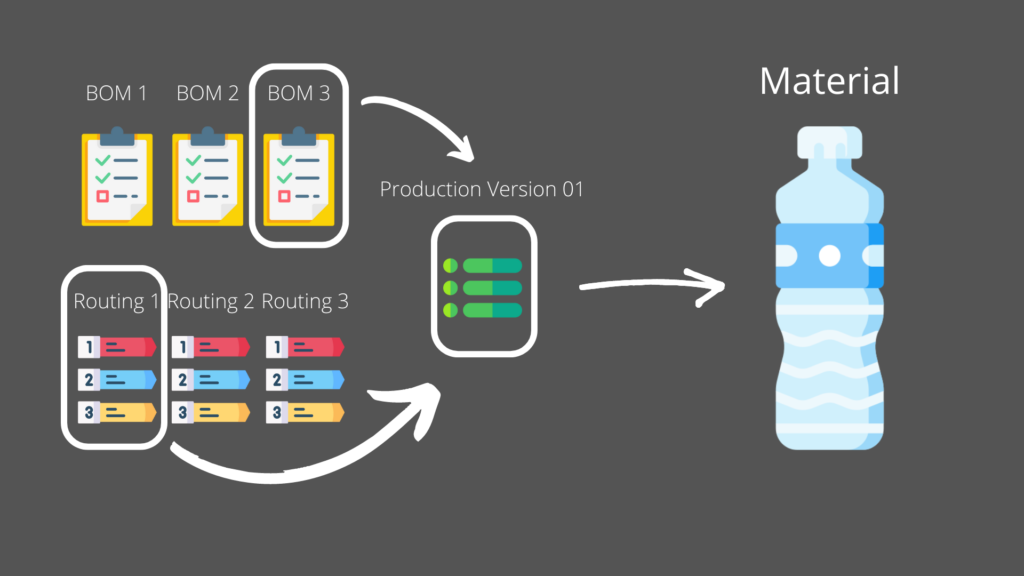

As explained above, it defines the different production methods for a material. Indeed, a material can be produced using several different methods.

First of all, a material can have one or more BOMs. This means that for the production of the latter, it is possible to use different material lists, which lead to the same result.

Secondly, a material can also have one or more routings. This means that for the production of the material, it is possible to use different lists of operations, which bring to the given outcome.

The aim is to define a single range and bill of materials pair for the production of this equipment.

What are the functionalities?

In addition to defining a unique pairing between a routing and a bill of material for the production of a material, a Production Version also allows control functions to be established.

Firstly, it is possible to configure a specific value for a production quantity range. For example, it is possible to create a Production Version with a production quantity from 1" to 5000", or one dedicated to productions of over 1000".

Furthermore, it is also possible to configure a specific value for a validity period. For example, it is possible to create a Production Version between 01.01.2022 and 31.12.2022.

How do I create a Production Version?

In order to create a Production Version, there are two different methods.

The first method is to use the Report CS_BOM_PRODVER_MIGRATION, which allows you to create mass production versions. This is a report made available by SAP to generate production versions during the migration to S4/HANA, or in the context of a new implementation.

The second method is to use the functional transaction C223.

Path : Logistics > Production > Master Data > Production Versions

In the upper part of "Selection Conditions", you must enter at least the Plant and the Material for which you want to create a Production Version, then validate. If one or more Production Versions exist for the material indicated, they will be displayed in the lower table "Production versions".

To view the details of a Production Version, please select it and click on the "Detail view" icon. The information of this version (range, bill of materials etc...) will appear in a new pop-up window.

To create a new Production Version, simply click on the "Create" icon in the menu bar, above the lower table "Production Versions" and fill in the necessary information, such as the material number, the Production Version number, the Production Version description, the validity dates etc.

Once created, the Production Version will automatically be assigned the status "Not yet checked", corresponding to the yellow triangle in the "Status Consistency-check" column :

It will then be necessary to select the new Production Version and perform the Consistency check by clicking on the corresponding button. A new pop-up will appear and inform the user of any inconsistencies :

MRP4 Material Master

Once your Production Version has been created for your material, it is possible to retrieve them in the Material Master and more precisely in the MRP4 view :

Would you like to improve your SAP skills? You can access our free training courses, or opt for our premium "Beyond the Horizon" (SAP beginners) or "Expert Training Center" (advanced) courses.

Pierre Balbinot

SAP functional consultant, EAM (Enterprise Asset Management) and PP (Production Planning) expert.