In SAP, the notion of Bacth is crucial. Indeed, this functionality is used in most of the companies that requirehave an increased traceability of their products, their process or their quality control. This term appears everywhere in the software: in MM (Material Management), in SD (Sales and Distribution), in WM (Warehouse Management) or in QM (Quality Management). But today, we will focus on the PP (Production Planning) part and we will see how SAP PP batch determination works.

But first of all, what is a batch in SAP?

Definition of the term "Batch".

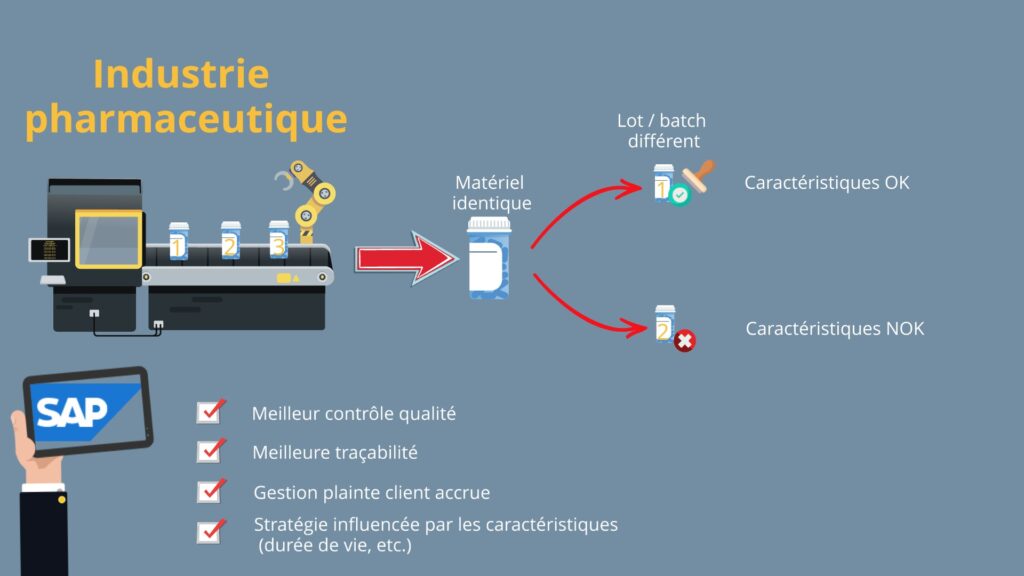

A batch is defined by a partial quantity of an article or product that have the same characteristics in common. Since a picture is worth a thousand words, here is how this term could be explained:

Thus, it can be understood that, despite an identical product, it can be manufactured differently, at separate times and can therefore have distinct properties / characteristics. It is therefore attributed a unique batch.

To find out more, I refer you to our guide dedicated to Batch Management for beginners:

There are many use cases for these batches. Indeed, as seen previously, they are found in most of the SAP modules. But today, we are going to focus on a very specific case : SAP PP batch determination.

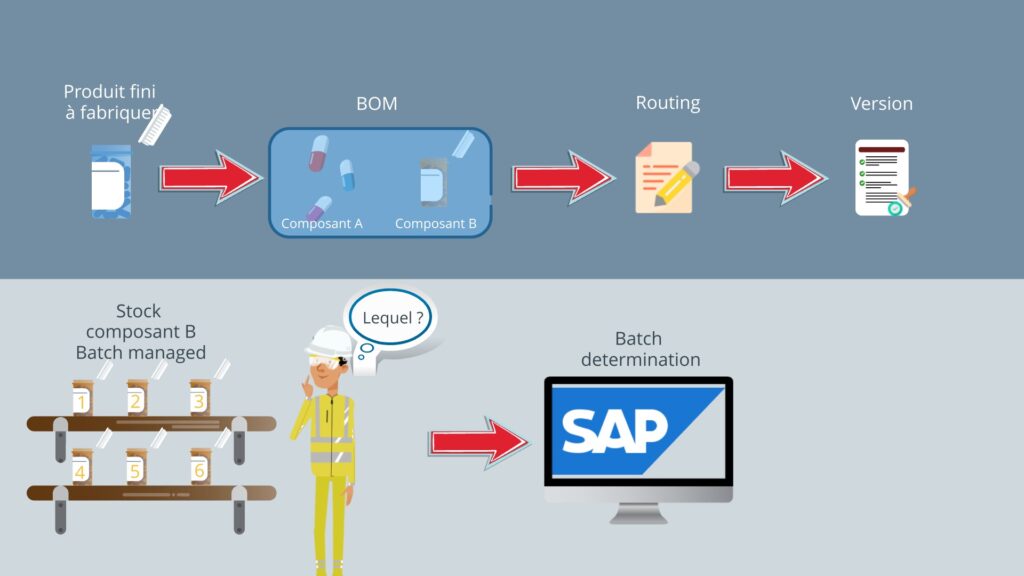

In production, to manufacture a finished product, several elements are usually required:

But since the components are also managed in batches, how do you choose the right one?

SAP then comes into play to help us determine this, based on predefined rules. But, to do this, we need to specify them. To make it easier to understand, let's analyze a concrete example.

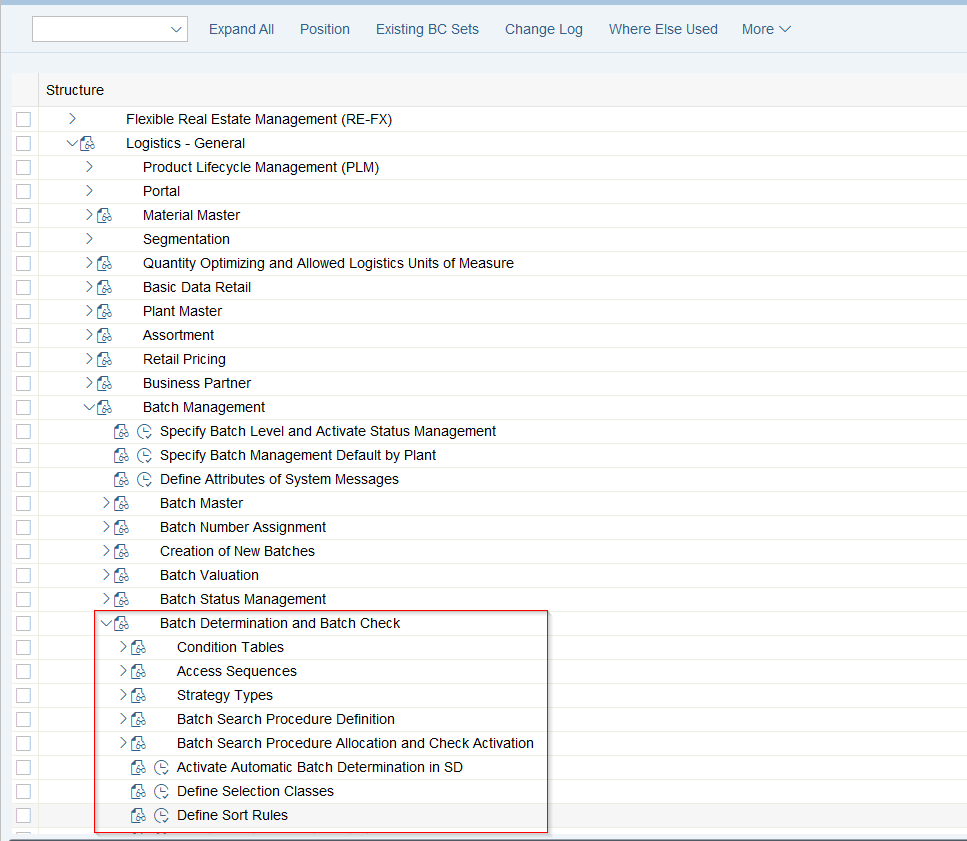

SAP batch determination – configuration

First of all, go to the customizing of SAP :

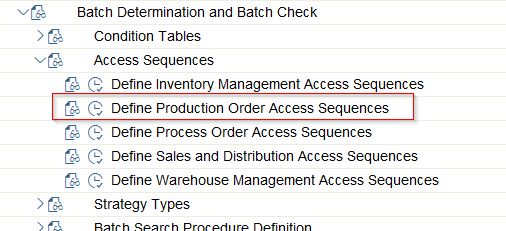

SPRO : Logistics - General / Batch Management / Batch determination and batch Check

Step 1 : Condition Tables

First of all, you will have to create/use a condition table. This parameterization point allows you to define the combination of data that will be used for the research strategy. Here, we will start with table 030 which includes the following data:

Hence, these criteria will be used for our research strategy.

Step 2 : Access Sequences

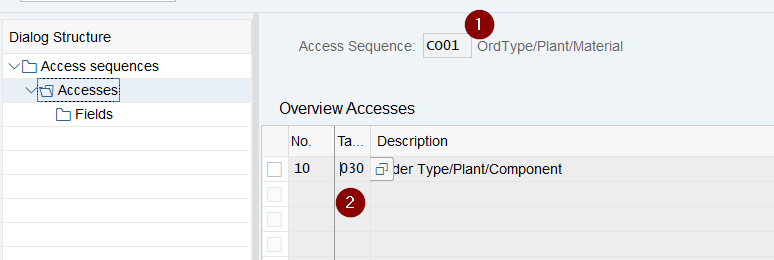

Next, turn to the "Access Sequences" item. The purpose of the latter is to go search the condition tables seen before and define a sequence, if needed. Indeed, it is possible to implement a strategy based on « Order Type / Plant / Material » and if no material is detected, then SAP searches the « Order Type / Plant » only.

For our purposes, we will use this sequence : CO01

The check is made only on condition table 030.

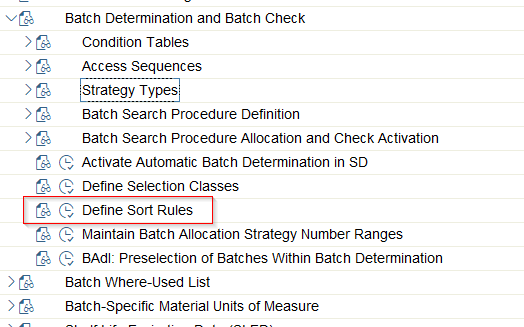

Step 3 : Define Sort Rules

So, in this part, we will define how the research is to be carried out, according to which order, according to which characteristics.

When creating these Sort Rules, you will choose the characteristics that will be used as reference, and in which order they should be sorted.

Here, the chosen characteristic is the batch number and the sorting is done in ascending order:

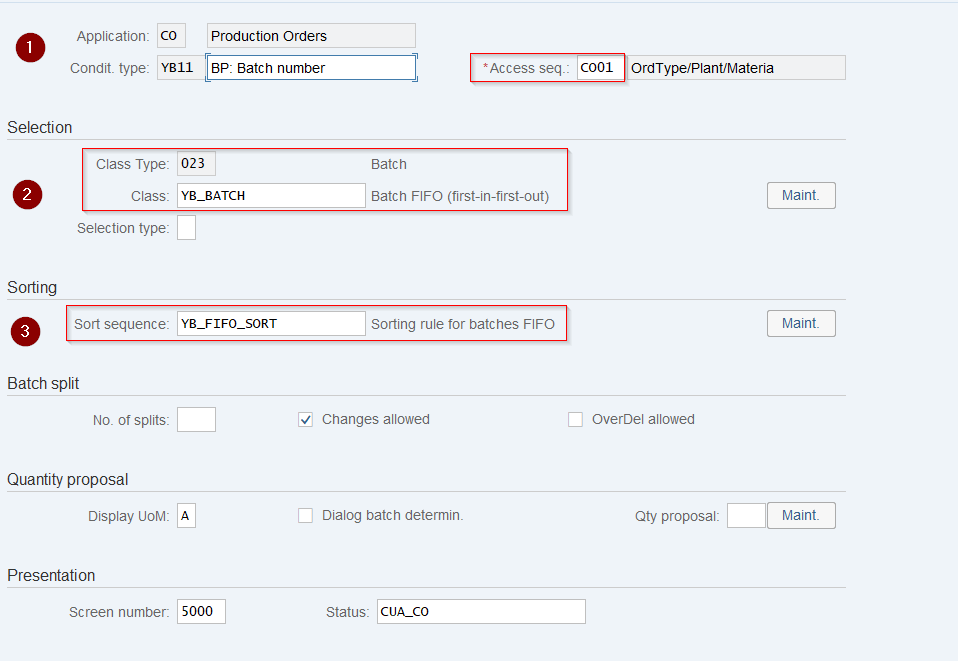

Step 4 : Strategy Types

Here we define how the search will be performed, based on the following configuration points. It is through this parameterization point that the whole search strategy will be defined. Let's look at the 3 most important parts of this setting point:

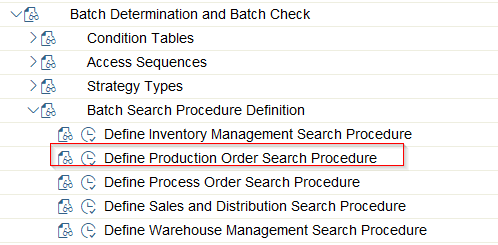

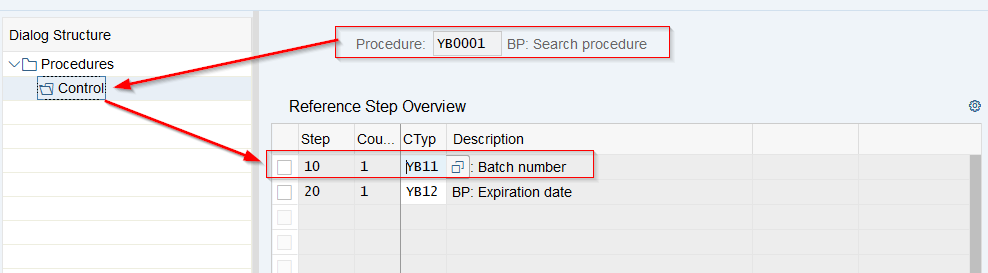

Step 5 : Batch Search Procedure Definition

Just like the Access Sequence, where it is possible to assign several condition tables, it is possible here to allocate several search strategies to our Batch Determination.

Here you must indicate the Condition Types to be used (the Strategy Type created earlier) and specify the order in which it should be processed.

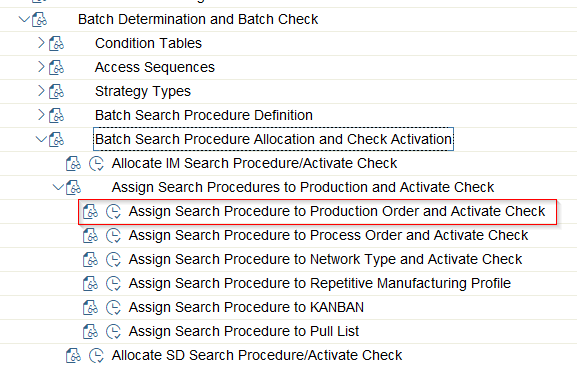

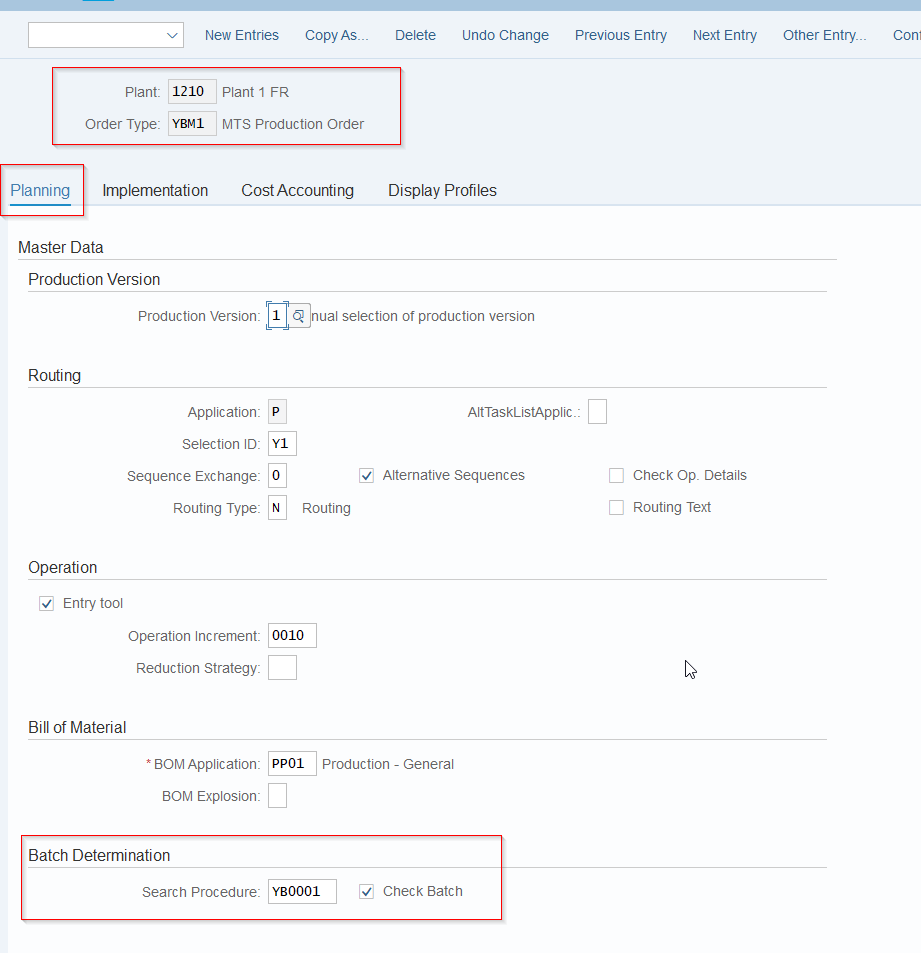

Step 6 : Assign Search Procedure to Production Order and Activate Check

Finally, let's go to the last step of the "Configuration" section. This is where we will assign our previously defined strategy, in the "Order Type-Dependent Parameters : Overview" point. This point, composed of the "Plant/Order Type" key, groups together a number of important fields in Production Planning, based on the defined Order Type.

What we are interested in here is the "Batch Determination" part. Thus, inform the Search Procedure seen earlier. This will then allow SAP to know, according to the Plant and the selected Order Type, if it must activate or not the Batch Determination and especially how to carry it out.

We can also note the check box "Check batch" which will also check the manually filled batches, by checking that they correspond to the defined strategy.

SAP batch determination – Material Master Data

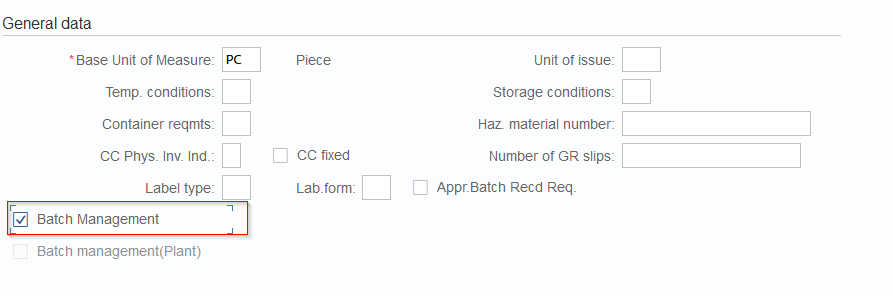

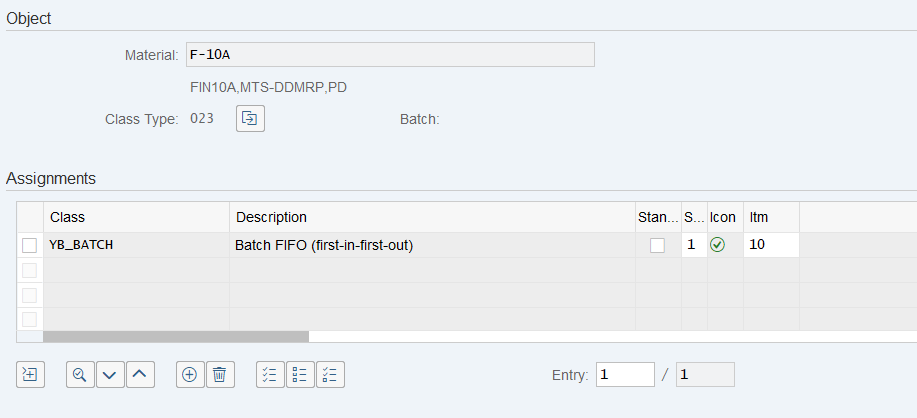

By the way, let's take some time now to configure the material where we would like to implement the automatic determination. For this, let's go to the Material Master Data of our article :

SAP batch determination – Conclusion

In short, we have seen all the points that need to be implemented to allow SAP to help you assign a batch. Indeed, it is not always easy to know which one to use, but above all, the time saving and the reduction of errors make this functionality an indispensable part of the PP (Production Planning) module.

What about you? Do you find this function essential in the world of industry? Do not hesitate to leave a constructive comment, but also to ask your questions in case of remarks, misunderstanding.

Would you like to improve your SAP skills? You can access our free training courses, or opt for our premium "Beyond the Horizon" (SAP beginners) or "Expert Training Center" (advanced) courses.

Michael Antoine

SAP technical-functional consultant, WM (Warehouse Management) and eWM (extended Warehouse Management) expert.

SAP Software

A very good article! I especially like that it explains how to set up a SAP as it's an easier way to understand and understand how it works. Thanks for sharing! Greetings.

Walter

Muy bien explicado. Pero tengo una duda: si yo quiero que el Lote sea obligatorio sólo desde la Entrada de Mercadería y no desde el pedidio, ¿cómo podría hacer? Es decir, no quiero que al momento de crear el pedido de compra me pida como obligatorio el lote, sino recién en la EM.

Gracias!

keyusertraining@gmail.com

What kind of document do you use in your order?

Doddeshi

Very good article

Bernabel

Is it possible to value by BATCH the same article but different prices and values depending on the batch and the possibility to value my stock by BATCH?

keyusertraining@gmail.com

Yes, it is possible to value inventory by batch, assigning different values to specific batches of the same item. This method makes it possible to accurately track the value of inventory according to the variable purchase or production costs of each batch. ERP systems, such as SAP, offer features for managing and valuing inventory by batch, using methods such as weighted average cost, FIFO (first-in, first-out), or LIFO (last-in, first-out) specific to each batch. This approach improves the accuracy of financial data and helps to manage inventory more efficiently.

Fernando

Tengo una consulta, en la determinacion dentro de la MIGO el sistema me propone cantidad x lotes y me los acomoda por el vencimiento mas reciente PERO me trae cantidades que estan en status de bloqueo o No Libre que no quisiera que el usuario pueda seleccionar ¿es posible esto?

keyusertraining@gmail.com

Sí, es posible evitar que el sistema proponga cantidades que están en estado de bloqueo o no libre en la transacción MIGO. Para ello, debe configurar la estrategia de gestión de stocks en SAP para filtrar únicamente los stocks disponibles en estado "libre" (Unrestricted use) y excluir los stocks en estado "bloqueado" (Blocked stock) o "no libre" (Quality Inspection stock).

Victor Angoa

Hola a todos, soy un poco nuevo en esto y necesito saber donde poner un candado cuando un lote alcance su FPC fecha preferente de consumo. En s4h

keyusertraining@gmail.com

Para bloquear un lote al alcanzar su FPC en S/4HANA, configura un estado de lote restringido. Ve a la transacción MSC2N (Modificar Lote), selecciona el lote y ajusta el estado a "restringido" manualmente o automatízalo usando una estrategia de liberación de lote en SPRO en Gestión de Calidad (QM).

Jesus EHernandez L

Hola buen día interesante, mas tengo una duda si quiero que me cree automáticamente lotes para determinados NP que transacción debo utilizar, ya que físicamente mi forma de ordenar el almacén en storage locations es dado debido al lote, y al consumir en el sistema toma esa locación mas próxima ejem: A0101RM - A0102RM - A0103RM, sin seguir fifos en sistema y con ello genera un des balance al realizar un inventario físico vs sistema