For large companies with complex inventory management, SAP enables them to segment their requirements planning according to several criteria. Whether it is at the Plant level, the Storage Location level or even when talking about subcontracting, SAP allows you to adapt your MRP to your needs, using what is called SAP MRP area.

But first of all, what is an MRP?

SAP MRP : Definition

MRP is an acronym for “Material requirement planning". This part of the SAP software allows you to calculate and anticipate the need for materials based on customer orders, part reservations, etc. This need will then generate a reaction from the software, by creating a production order or a purchase order.

Without going into technical details, here is how an MRP works:

Definition of the need

First, SAP will accurately determine the need (what to produce, what to buy, etc.).

Quantify the demand

Then, it is necessary to calculate the quantities required and the date of need to meet the demand.

Determine procurement

Finally, SAP checks the components, those that must be produced, purchased, compares with the quantities available via inventory, verifies the procurement or production times to finally determine the exact start date and sends the information to the purchasing/production department.

One can then easily realize that the calculation can be complex and that a lot of parameters can be taken into account. One of them is called SAP MRP area and this is what we will see together right now.

SAP MRP area : Scope

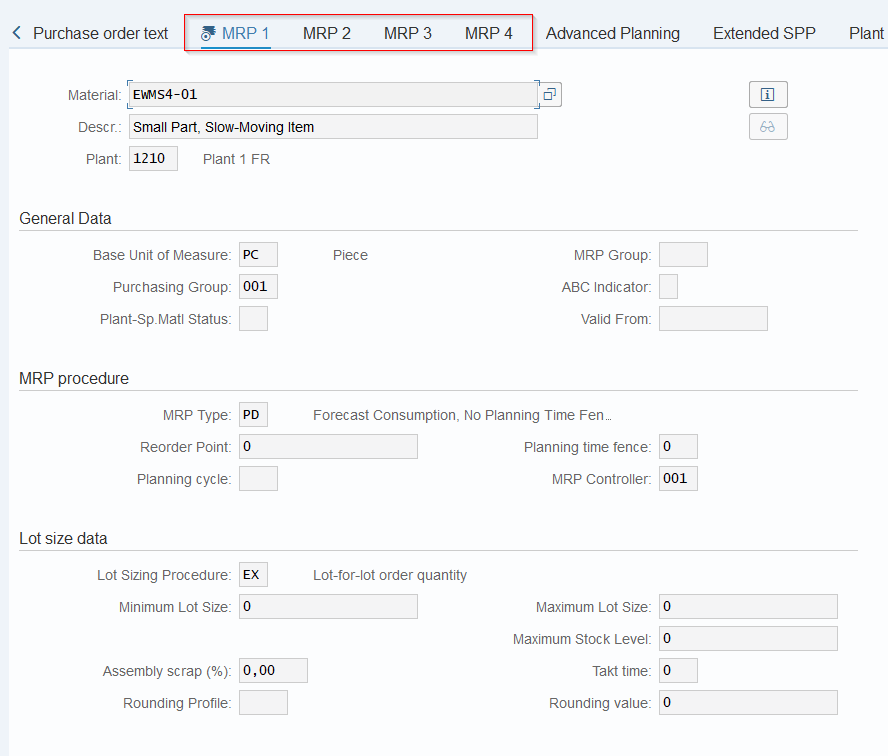

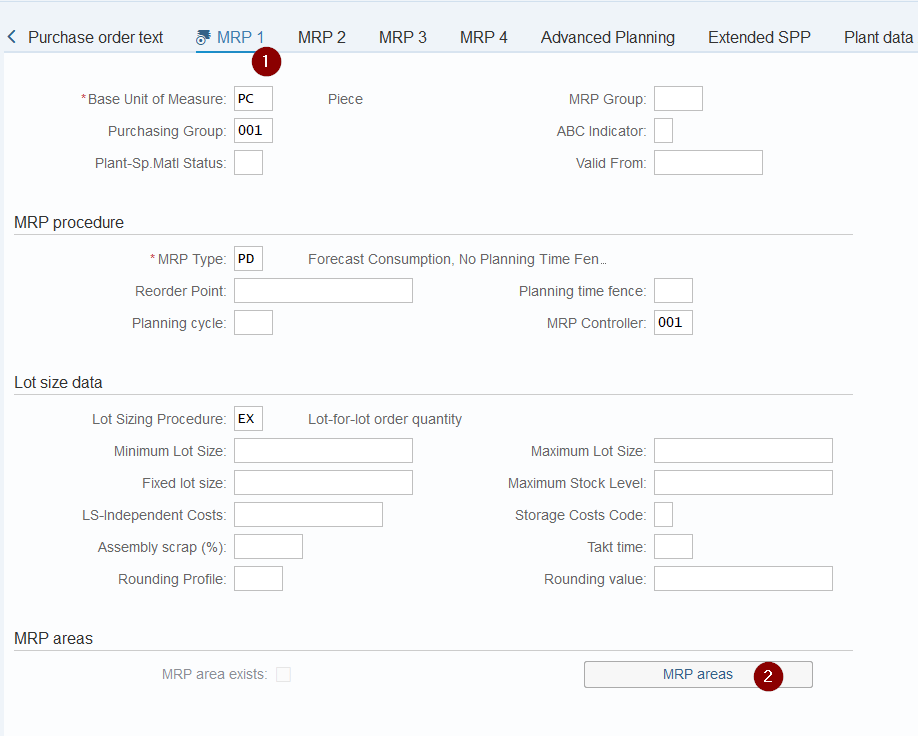

Initially, SAP calculates the requirement based on the Plant itself. As each material is different, all MRP information is located at the material level in the MRP views :

However, some parts can be located in the same Plant, in different Storage Locations and can be managed differently depending on the area / need. This is where SAP MRP area comes into play. Indeed, this functionality allows to define MRP zones for the same material, and assign specific needs to each of them.

Here's how it works:

But before assigning MRP areas to materials, you must first create these areas. This is done through customizing.

SAP MRP area : Configuration

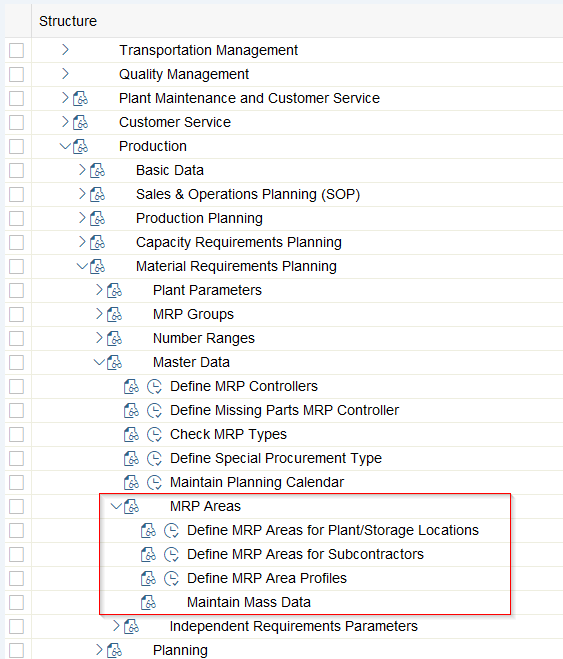

We can go in the customizing

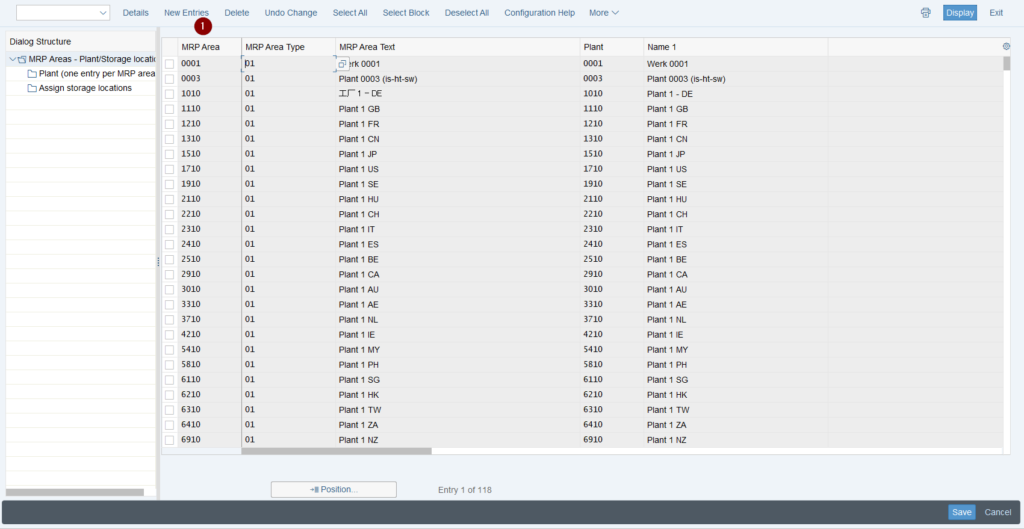

SPRO : Production / Material Requirements Planning / Master Data / MRP Areas

Here it is possible to create MRP Areas of 3 different types :

Plant

Here, the system will check the whole Plant. Identical to the classic operation.

Storage Location

Here it is possible to assign 1 or more Storage Locations. The system will then calculate the requirement on these.

Subcontracting

Here it is possible to assign 1 supplier for everything related to subcontracting.

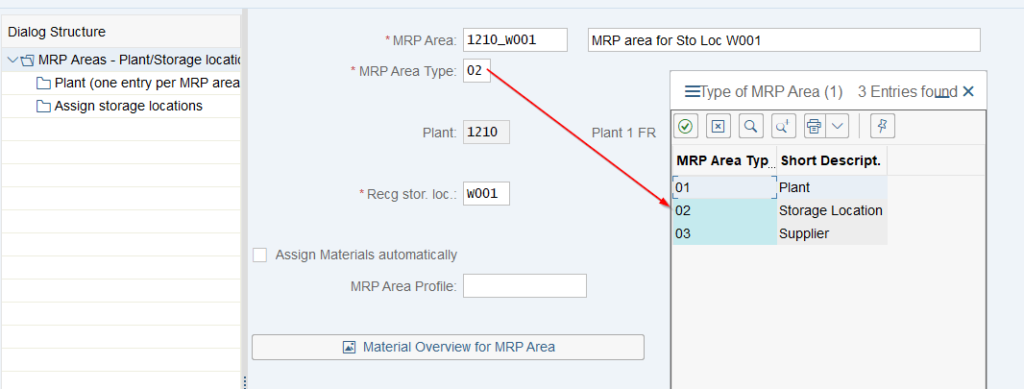

For our example, we will create an MRP area for 1 Storage Location in particular.

Here we will make a new entry. It is then necessary to fill in the following information :

Now you just have to save, assign our change to a transport request and the creation of the MRP area is finished. Now let's assign it to a material.

SAP MRP area: assignment

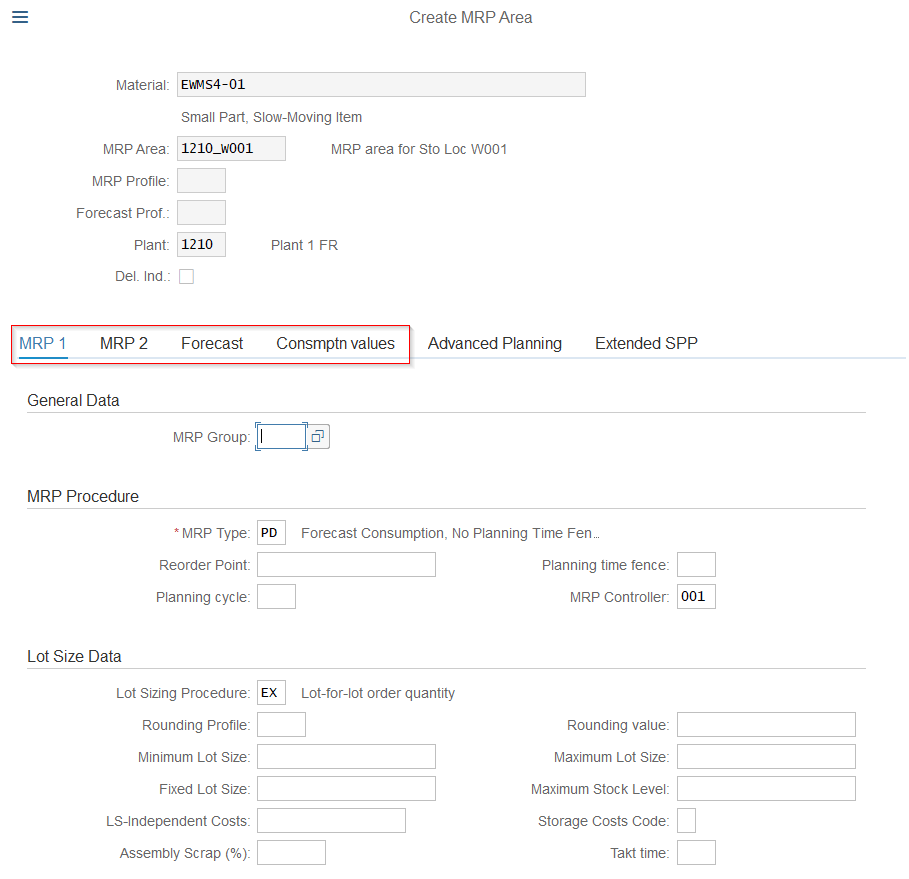

For this part, go to the Master Data part of the material, in the "MRP 1" view. Click on the "MRP areas" button and choose the one created previously.

Once selected, it is then possible to define the MRP parameters specifically for this MRP area :

SAP MRP area : conclusion

We didn't go into the details of how to use MRP, etc. Nevertheless, it has allowed you to see an SAP feature that allows you to fine-tune your MRP strategy to best meet business needs.

Don't hesitate to share your discoveries with us in the comments and, above all, don't hesitate if you have any questions or misunderstandings.

Would you like to improve your SAP skills? You can access our free training courses, or opt for our premium "Beyond the Horizon" (SAP beginners) or "Expert Training Center" (advanced) courses.

Michael Antoine

SAP technical-functional consultant, WM (Warehouse Management) and eWM (extended Warehouse Management) expert.

Malick chérif haidara

This is very important. I really want to understand the MRP.