In any company, regardless of its business, cost management is very important. Every company is very concerned about it. Each department, and especially the maintenance department, has its own card to play when it comes to cost optimization. SAP Plant Maintenance contains, of course, a whole area related to cost management. Let's discover how it works through this article SAP PM - Cost Management.

Cost optimization

In the world of industry, the maintenance department represents a major expense item, if not one of the main ones. Therefore, it is normal for companies to do everything possible to reduce its costs.

Instead of sacrificing machine condition, service quality or equipment reliability, managers prefer to turn to innovative solutions. By innovative solution, we mean the use of management software.

The Plant Maintenance module proposed by SAP contains an entire section dedicated to cost management, which is closely linked to the FI CO modules. Thus, thanks to its numerous available data, SAP PM offers a thorough and complete cost analysis, which converges towards cost optimization.

The three types of costs

First of all, SAP Plant Maintenance uses three types of costs, of which two main ones: Planned Costs and Actual Costs. You will also be able to find a third type of cost, the Estimated Costs.

Indeed, the planned costs and the actual costs are calculated and generated automatically by the system. On the other hand, the estimated costs are not calculated. Therefore, these costs must be entered manually in SAP.

Estimated Costs

The estimated costs are costs to be entered manually in the system. Indeed, they are only based on the empirical values of a maintenance planner and not on planned resources.

Planned Costs

Planned costs are costs calculated automatically by the system. They are based on a detailed resource planning. They provide an overview of the costs that could be incurred by a maintenance order.

Current Costs

Like the planned costs, the actual costs are costs that are automatically calculated by the system. These are updated in the context of time confirmation, parts consumption, etc...

Cost visualization

By its nature, a maintenance order generates, in most cases, costs. Whether it is within the framework of internal and/or external manpower or in the case of use of internal and/or external materials.

Thus, a maintenance order contains a "cost" tab, which allows a detailed visualization of the costs it has generated. These costs can be displayed in two different ways: by Value Category or by Cost Element:

Value Category

Value Categories are groups of values that contain one or more Cost Elements. As a rule, five Value Categories are maintained: internal service, external service, internal material, external material and other.

Cost Element

The Cost Elements allow you to classify and analyze costs according to their origins. Moreover, there are two types of Cost Elements: primary costs and secondary costs.

Via these two possibilities, you have the choice between detailed cost reporting (by Cost Element), or rather grouped (by Value Category).

Note: in general, this is the option by Value Category that is most used.

In addition, SAP Plant Maintenance offers a detailed cost view by operation, or globalized via the header. It will therefore be possible, according to the needs of the business, to parameterize the granularity of the information.

In the first case, at the operation level, each operation will display its own costs, according to the three types (Estimated costs, Plan costs & Actual costs) and according to your configuration (Value Category or Cost Element).

In the second case, at the header level, the system displays only the total values. Thus, these values correspond to the sum of each cost for each operation. Finally, as in the previous case, these will also be displayed according to the three types (Estimated costs, Plan costs & Actual costs) and according to your configuration (Value Category or Cost Element).

Reporting tools

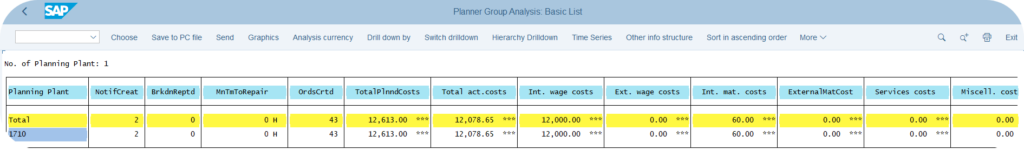

Indeed, SAP Plant Maintenance offers many reporting transactions that allow to analyze the costs generated by maintenance orders. To mention only two of them, we can take the example of the functional transactions MCI2 – Manufacturer Analysis and MCI4 – Planner Group Analysis:

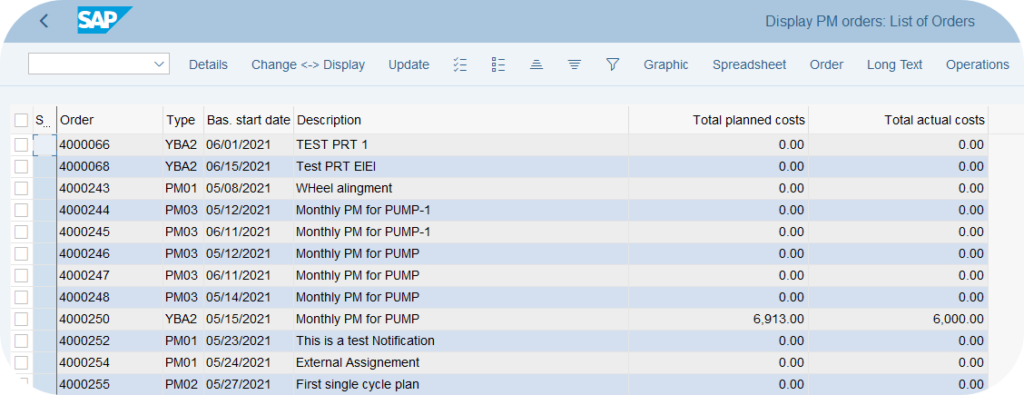

In addition, you also have the possibility to perform a cost analysis via standard functional transactions. Let's take the example of the transaction IW39 - Display order list. By modifying the Layout, you can add several cost columns:

Finally, many companies use the consolidation of cost data via the BO (Business Object) / BW (Business Warehouse) module to generate KPi on cost data. This method allows for an even more advanced and efficient analysis possibility.

Would you like to improve your SAP skills? You can access our free training courses, or opt for our premium "Beyond the Horizon" (SAP beginners) or "Expert Training Center" (advanced) courses.

Pierre Balbinot

SAP functional consultant, EAM (Enterprise Asset Management) and PP (Production Planning) expert.

project management

A great post! It certainly helps to understand how to do optimal account management via SAP

MELANY

BUENAS TARDES, ACTUALMENTE NOS ENCONTRAMOS EN BUSQUEDA DE UN PROGRAMA INFORMATICO PARA LLEVAR A CABO LOS DIFERENTES TIPOS DE MANTENIMIENTOS, COSTES Y CONTROLES FACTURACION. Y NOS GUSTARIA CONOCER MAS A FONDO ESTE PROGRAMA SAP YA QUE ME HAN HABLADO DE EL EL COSTE QUE TIENE Y SUS APLICACIONES.