First and foremost, the order-picking process is an essential part of logistics, and its efficiency has a direct impact on customer satisfaction and operational costs. To optimize this process, many companies are adopting SAP WM 2 Step Picking, a method for improving order-picking productivity and accuracy.

So, in this article, we'll explore the concept of 2 Step Picking in logistics (WM) and its application in SAP. We'll discover the advantages of this method over traditional approaches, how it works in two stages, and the steps required to implement it successfully.

SAP WM 2 Step Picking: benefits and operation

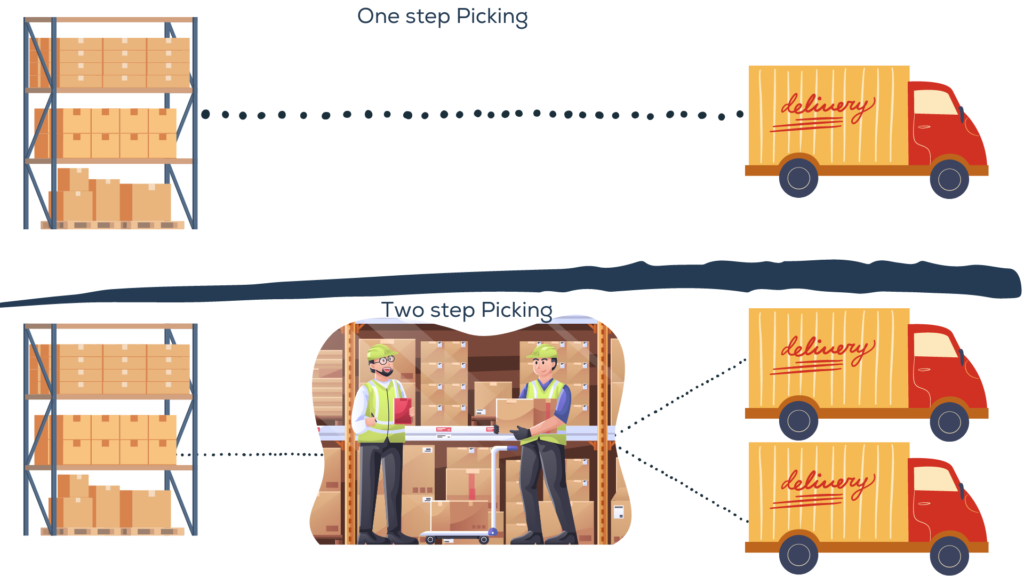

Indeed, 2 Step Picking offers several significant advantages over traditional order-picking methods. First and foremost, it significantly improves productivity by reducing unnecessary operator movements. By dividing the picking process into two distinct stages, initial picking and confirmation picking, workers can concentrate on one task at a time, reducing errors and speeding up the overall process.

The 2 Step Picking process is relatively straightforward. In the first step, operators prepare the required items from the storage locations. These items are placed in bins or carts, ready for the second step. In the second stage, confirmation picking, operators check and confirm the items in the bins or carts before moving them on to dispatch.

SAP Warehouse Management (WM) offers a complete solution for implementing 2 Step Picking. In addition, it enables picking strategies, storage types and priority rules to be configured to suit the specific needs of each company.

Configuration of SAP WM 2 Step Picking

So the right configuration of 2 Step Picking in SAP Warehouse Management (WM) is essential to ensure that it runs smoothly and is aligned with your company's specific needs. Here are the key configuration steps:

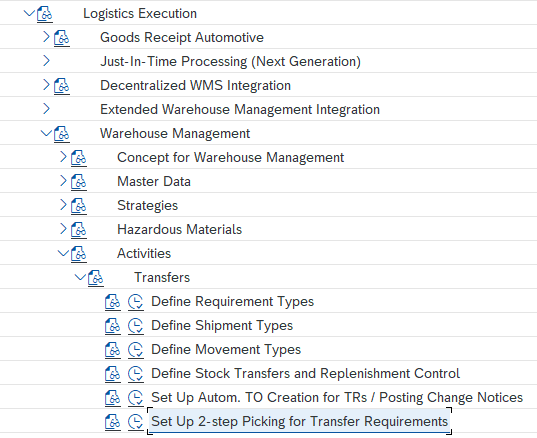

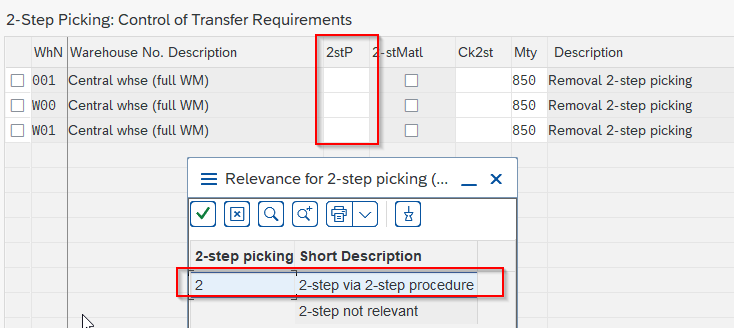

Activate Two step picking for Transfer Requirement

SPRO : Logistic Execution - Warehouse Management - Activities - Transfers - Set up 2 step picking process for Transfer Requirement

Transfer Requirement Control

Transfer Type Control

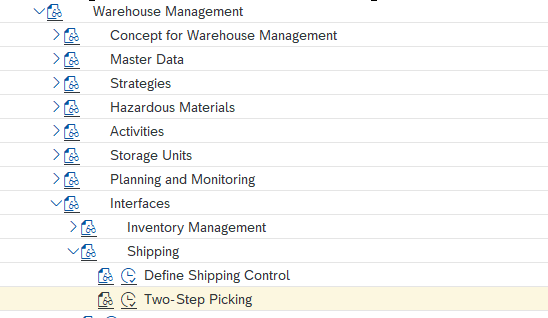

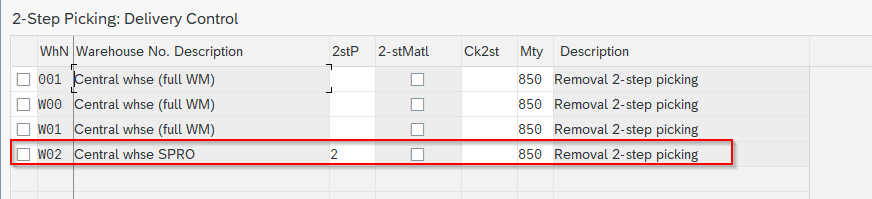

Activate Two step picking for shipping

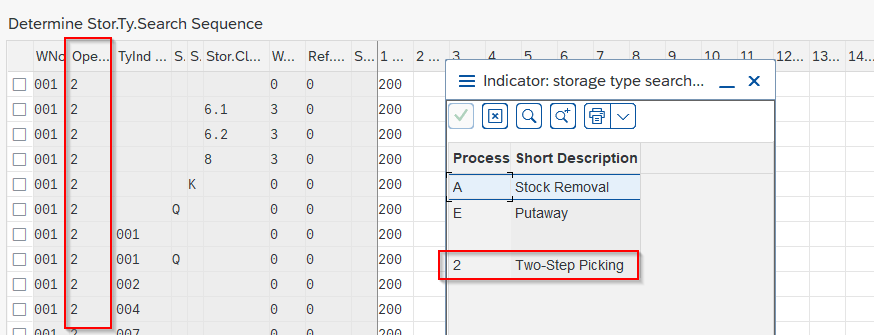

Activate Storage Type Search

SPRO : Logistic Execution - Warehouse Management - Strategies - Activate Storage Type SearchThe final step is to configure the Storage Type Search for 2 Step Picking. Here, we'll assign the number "2" to the operation and set Storage Type 200, which will serve as a temporary zone for our process.

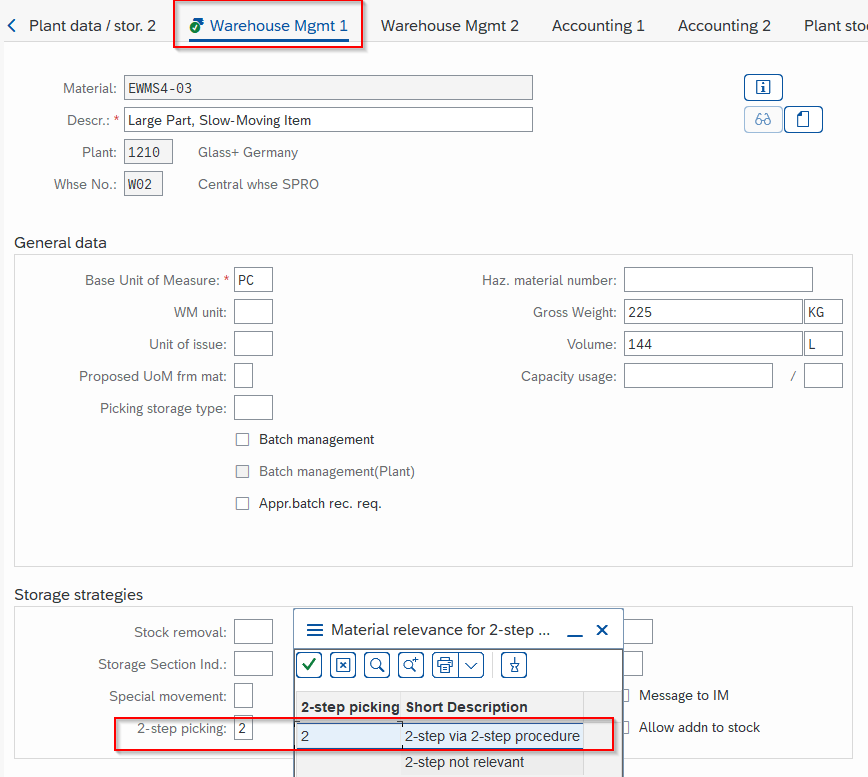

Material Master Data

Finally, if the 2 Step Picking process is hardware-dependent, then go to its item card, "Warehouse Management View 1" and indicate that it is relevant to use this functionality for the latter.

Finally, this completes the configuration.

SAP WM 2 Step Picking: Implementation

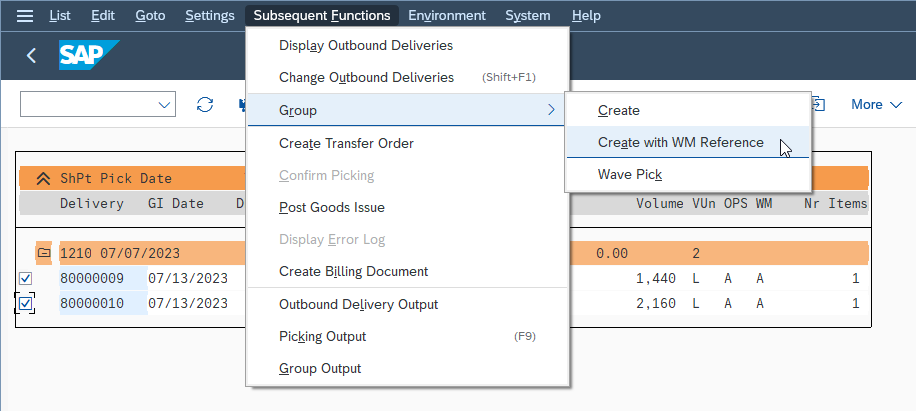

Next, the implementation of 2 Step Picking in SAP Warehouse Management (WM) begins with the creation of a group based on existing deliveries. In effect, these groups enable deliveries to be grouped together to create a collective TO (Collective Transfer Order), followed by the allocation of materials to the right deliveries. Here are the steps for implementing this approach:

Group creation

Or Transfer Requirements already exist. For example, in the case of a Posting Change Notice. In this case, we can use the LT41 to assign them a group.

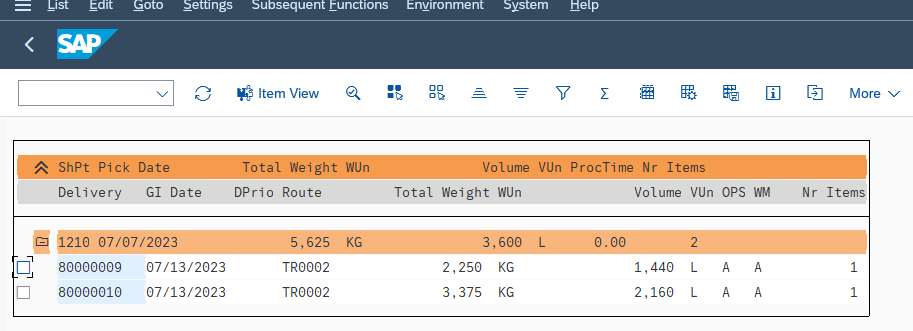

Either we rely on the existing Delivery, and use the transaction VL06P. In our example, this is the one we'll use:

SAP WM 2 Step Picking: Implementation

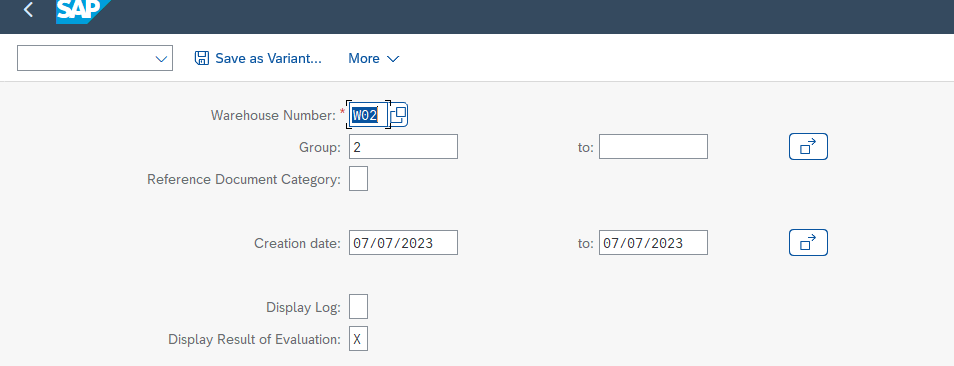

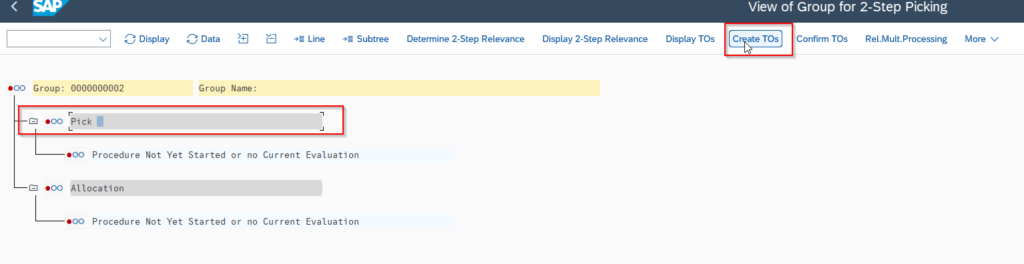

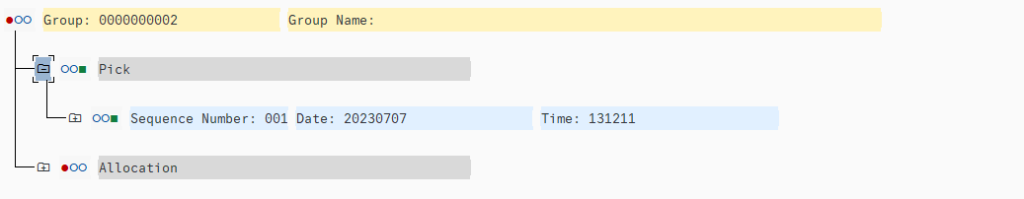

Finally, once our group has been created, let's use transaction LX39 to display our group. This transaction contains several sections. Firstly, the first step is represented by "Pick" and the second by "Allocation". Let's take a look at the entire process below:

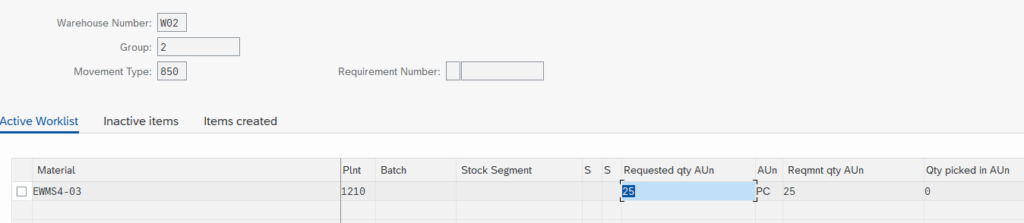

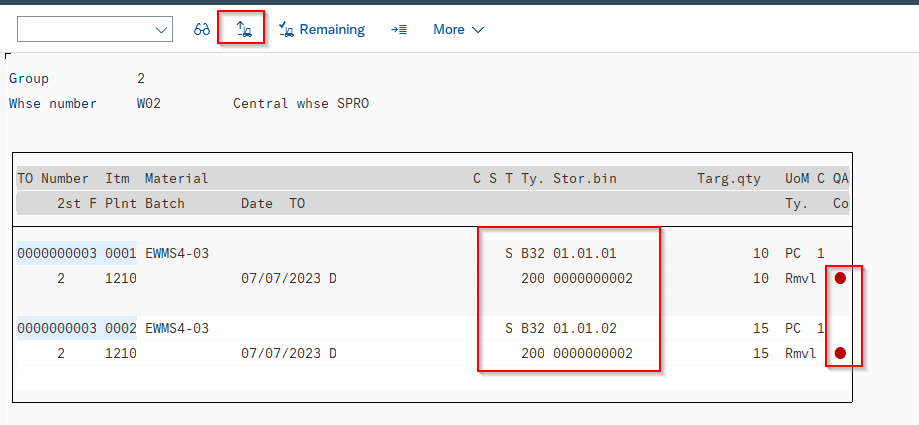

Next, let's carry out the Pick step to collect the parts and place them in the temporary zone:

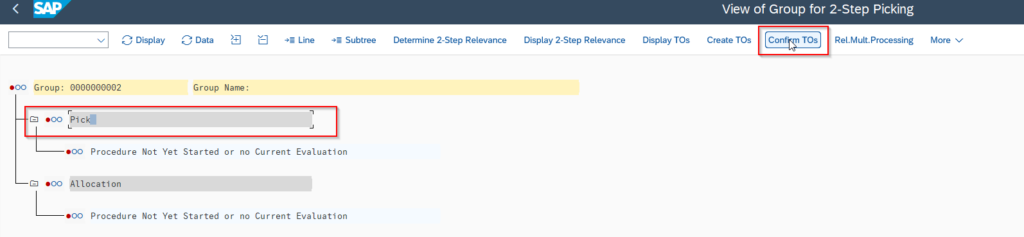

Then, once the transfer order has been generated, it must be confirmed:

Afterwards, you can see that the pick is complete, and that the parts have been transferred to Storage type 200.

Finally, the same operation needs to be carried out for the allocation part, which then dispatches the parts according to their respective Deliveries.

SAP WM 2 Step Picking : Conclusion

In conclusion, 2 Step Picking in SAP WM offers an opportunity to optimize your logistics by grouping deliveries and improving the efficiency of your picking processes. What's more, with its benefits in terms of reducing unnecessary travel and improving accuracy, 2 Step Picking can transform the way you manage your warehouse.

Would you like unlimited access to our entire SAP training library? Test our training platform free of charge for a 7-day trial period.

Michael Antoine

SAP technical-functional consultant, WM (Warehouse Management) and eWM (extended Warehouse Management) expert.

Leave a Reply