Have you ever been bluffed by companies like Amazon when you place an order and it arrives at your door before you even get home from work?

In fact, the logistics competition within companies is raging today and being ahead of the game requires considerable resources. In fact, whether it's department stores or companies and factories of all kinds, no one can escape the challenges of the supply chain.

Thus, the management of a company's assets, at all levels, requires efficient management and optimization of inventory. For example, if you are in the food industry, quality standards require you to maintain sufficient stocks of finished products to guarantee quality service to customers. But again, if you want to do e-commerce, know that setting up logistics and choosing your shipping methods is an important factor in success.

SAP has been able to adapt to these issues and therefore offers an effective solution with its module to help you: Logistics Execution.

The objective is to reduce the cycle time of the articles, while increasing the quality of the stocks, the availability of the products, by guaranteeing the traceability and the integrity of the information of the articles, while controlling the operational processes. In terms of inventory management, SAP software allows for accurate tracking of inventory and availability of items, material flows, maintaining the status of orders, performing physical inventories and monitoring evaluation indicators.

But first, let's start at the beginning. We need to understand how SAP hierarchizes its inventory management so that you can best define the structure of the warehouse.

SAP WM: Warehouse Structure and Inventory Management

SAP breaks down its inventory management into 2 parts :

Inventory Management

This consists in managing the physical stock of the company, in terms of quantity but also cost.

In SAP, this entity is represented by the notion of "Storage Location".

Warehouse Management

This part is in charge of the IT management of the stock, mainly in terms of location. In SAP, we will refer to the term "Warehouse number". In SAP, we will refer to the term "Warehouse number".

For an efficient management, it is essential that you link these 2 parts together. The first step is to create a Storage Location or use an existing one. So let's go to Customizing using transaction SPRO :

SPRO : Enterprise Structure / Definition / Materials Management / Maintain storage location

Furthermore, let's create or use an existing warehouse. Therefore, let's always go to SPRO :

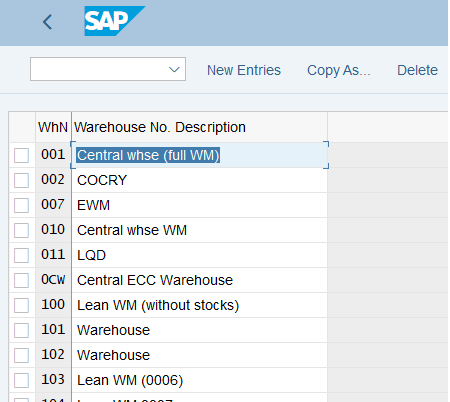

SPRO : Enterprise Structure / Definition / Logistics Execution / Define, copy, delete, check warehouse number

Finally, let's make the link between the 2 entities:

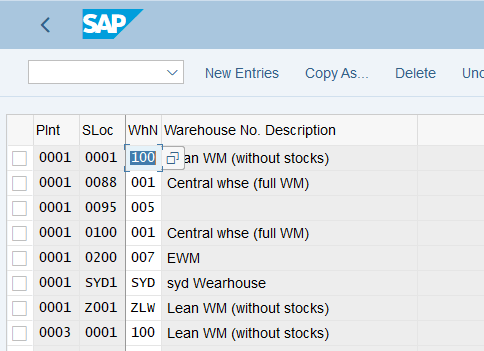

SPRO : Enterprise Structure / Assignment / Logistics Execution / Assign Warehouse number to Plant and Storage Location

Perfect! The basis for our Warehouse structure is established. In order to go further, we now need to define the composition inside the Warehouse. Let's go !

SAP WM: Warehouse Structure in Detail

Because a picture is worth a thousand words, let's look at how the Warehouse is broken down in SAP.

SAP WM: Warehouse structure, for which goal?

Indeed, we have discussed the structure of the Warehouse and detailed each entity of it. But why?

Let's consider for example a very large distribution company. This one has a huge storage area, several zones for receiving goods, shipping, storage and products of all kinds (food, electronic products, etc.).

The company's employees are organized into departments. For example, one person is in charge of storing products, another is responsible for shipping goods and so on.

This hierarchical organization is quite simple to understand, and vou can It's easy to imagine it being replicated in many smaller organizations. It is, however, very rigid. This means that goods need to be accurately received and then stored in the same way.

SAP, by providing the flexibility to replicate all parts of the entire warehouse, allows you to establish precise strategies on a case-by-case basis.

Here you can see an overview of what the WM module can offer you:

Would you like unlimited access to our entire SAP training library? Test our training platform free of charge for a 7-day trial period.

Michael Antoine

SAP technical-functional consultant, WM (Warehouse Management) and eWM (extended Warehouse Management) expert.

SAP WM 2 Step Picking: Optimize Your Order Picking Processes - SAP Training and Coaching

[...] must assign a particular movement, in this case 850, to move items to Storage Type [...].

Prachi Gupta

Great Learning

Amit

Good

keyusertraining@gmail.com

Thank you Amit for this comment 🙂